In 1981, ECKOLD first presented its innovative clinching technique and quickly brought it to market. Today, ECKOLD customers all over the world rely on this unique and sustainable joining method. ECKOLD clinching produces permanent connections by means of local cold forming alone, doing away with separate fixtures and auxiliary parts. ECKOLD offers an unrivalled range of joining options. Find the ideal clinching version for your specific joining task – be it for series production in automated plants or for manual joining with hand-held, portable devices.

Our services in the field of clinching

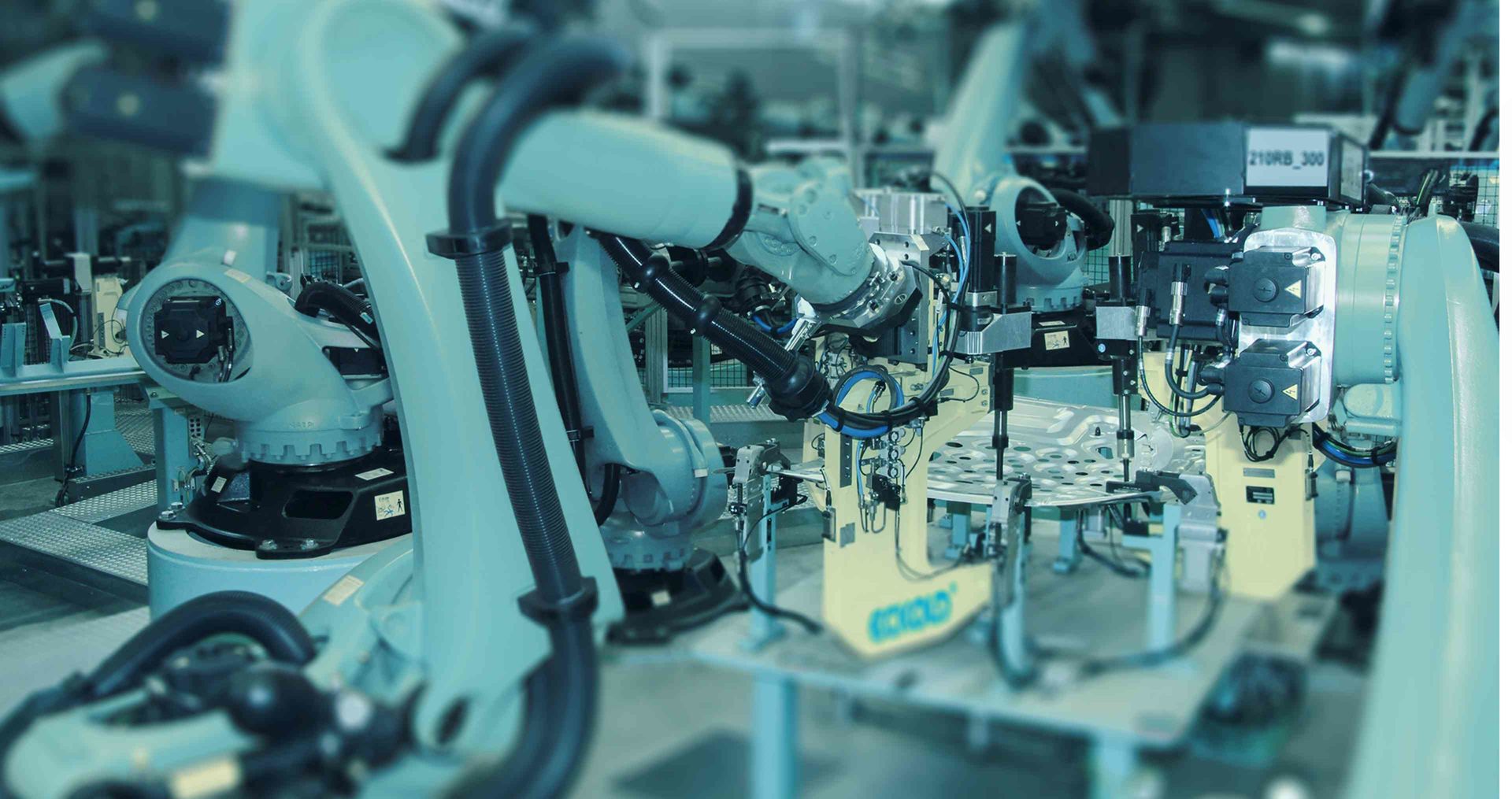

- Versatile range of portable and stationary machines, including units for automated production plants with or without robots

- Customised clinching pliers, frames, devices, systems and plants

- Feasibility studies, trial runs and sample production

- Technical planning, design, construction and manufacturing

- Competent advice and short response times

- On-site services (e.g. for commissioning)

- After-sales services (including staff training, online maintenance, process optimisation, etc.)

- Wide range of tools

FROM ALUMINIUM TO STAINLESS STEEL – CLINCHING JOINS THEM ALL

We at ECKOLD know that innovative technologies produce strong connections.

With clinching, you can permanently join nearly any metal or organic material,

even if the workpiece thickness varies, or more than two layers are to be joined.

Whatever you want to join – ECKOLD has the solution. The key to success are the right technique and the right tool.

And both are available from us!

For decades, leading automotive manufacturers have been relying on ECKOLD solutions. With ECKOLD clinching, you can make significant cost savings in car body production. Comparisons with other joining methods revealed that clinched joints are particularly durable – even under adverse ambient conditions. For the joining of mixed materials and/or materials of different thickness, clinching can often be performed with a single tool kit. ECKOLD clinching is also suitable for hybrid joining, i.e. clinching in combination with gluing. Thanks to the compact design of our clinching machines and the broad range of tools on offer, ECKOLD clinching is a highly versatile technique. Computer-aided process monitoring ensures continuous online supervision and documentation of the clinching processes, thus guaranteeing reproducibility.

Would you like to know more about clinching in your industry?

Contact us

Clinching is the ideal solution for all joints where precision and aesthetics are key requirements. This is for instance the case in the automotive industry, and car manufacturers and parts suppliers have for many decades been relying on ECKOLD clinching.

Other industries

Clinching is used in virtually all industries where sheet metal is being machined – by white goods and household appliances manufacturers, the HVAC sector, general fabricators, steel furniture producers and providers of shelving and storage solutions.